REALIZATION

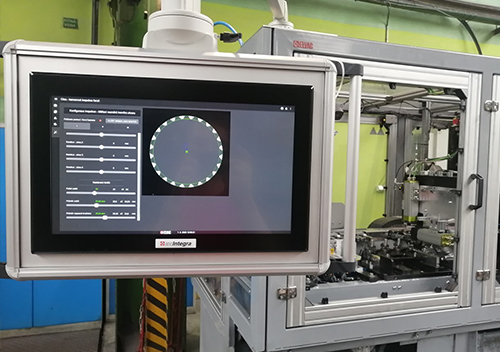

Separate workstation for application and curing of transparent silicone

The main task in this case was to create a reliable system for controlling the application of transparent silicone on printed circuit boards using ELVAC Vision.

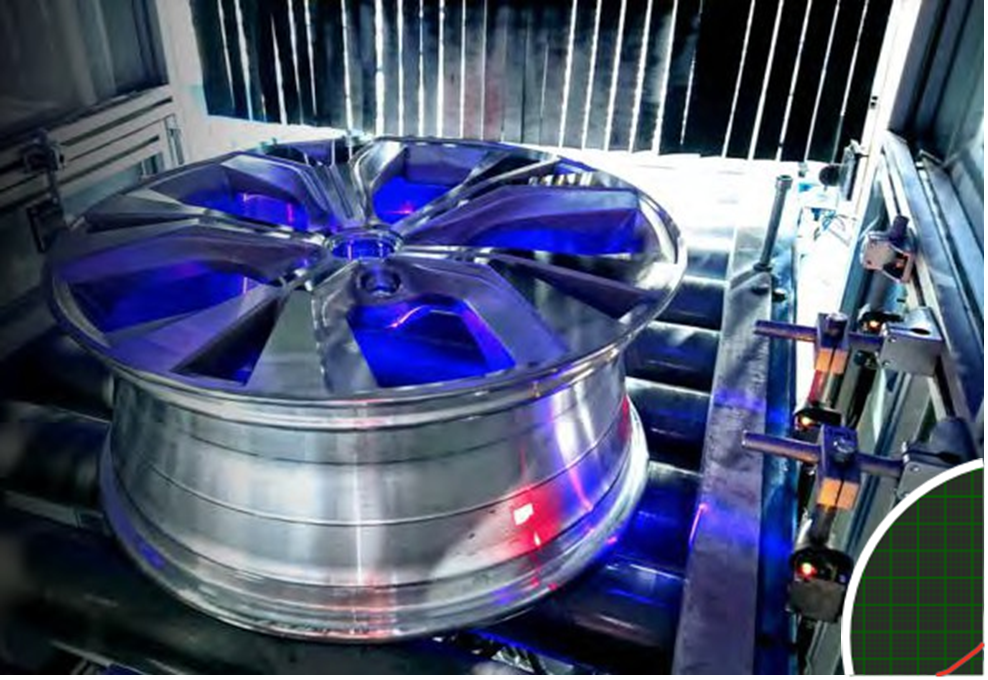

Robotic cell for precise sticker application on aluminium wheels

By combining the camera system and the robotic arm, we have created a functional unit designed for coating various aluminium wheels for car wheels.

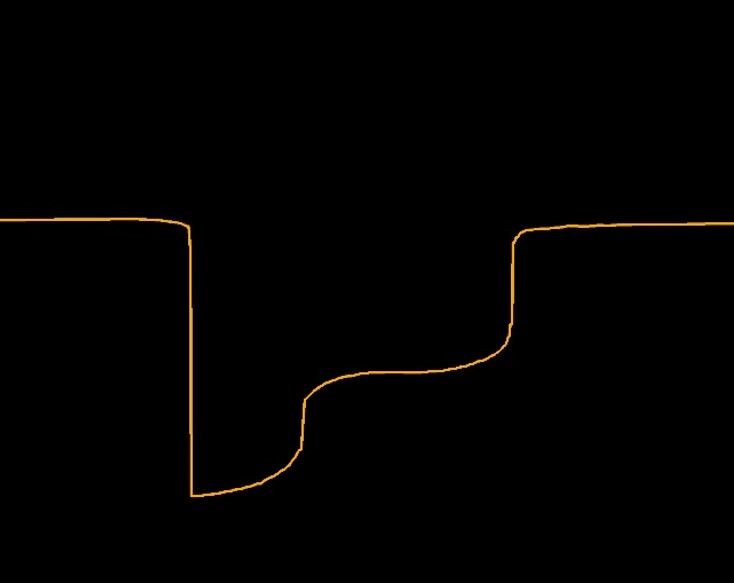

Workstation for the assembly of product housings with very precise measurement with profilometer and camera

It is a stand-alone workstation used to accurately assemble two parts of a product with a minimum gap width of less than 1 mm.

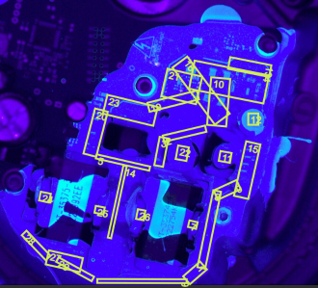

Integration of precision camera part measurement into existing workstation

Due to the increased quality requirements for the products, it was necessary to add an optical measurement with an accuracy of +-0.1 mm and an evaluation time of up to 100 ms.

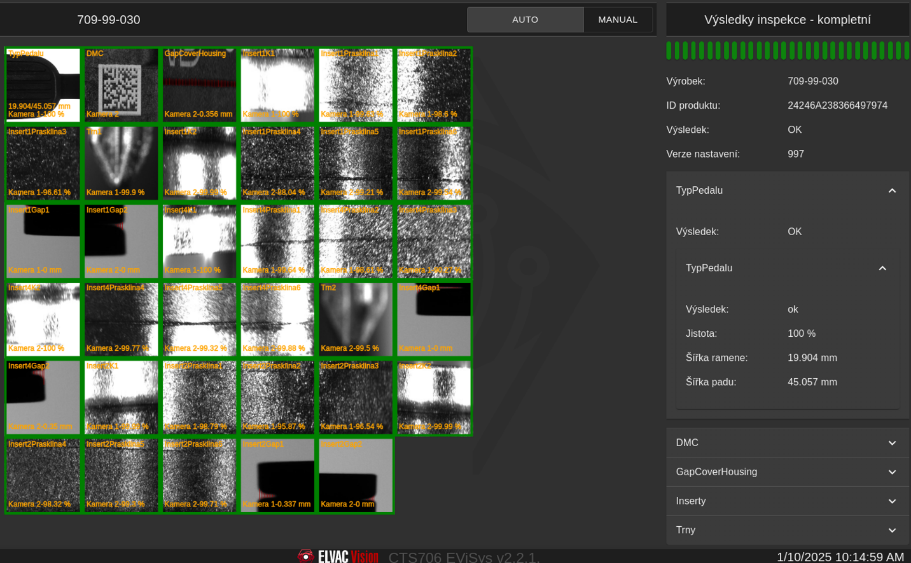

Comprehensive camera inspection at the output of the line in cooperation with the robot

We replaced the original output part of the line with a robot and two cameras for precise optical quality control of the products.

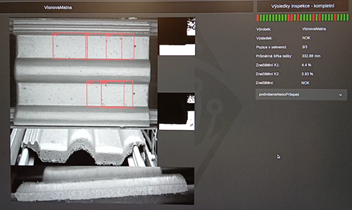

Measuring system for evaluating the surface quality of an aluminium wheel rim

In this project, we have developed a system that reliably detects porosity on machined aluminium wheels before they are painted.

Complete multi-camera inspection of products on the conveyor

We added two evaluation stations to the customer's existing conveyor line to detect paint spray quality, surface deformation and measure product width.

Optical deformation control on moulded parts in cooperation with a manipulator

We have integrated camera inspection into the press machines to capture possible underflows and upgraded the lighting required for reliable evaluation.

Automated station for winding aluminium wheels on a conveyor

We added a camera and a manipulator to the existing conveyor. Thanks to this, it is possible to find the correct rotation of the wheel and rotate it to the specified position with a maximum deviation of 3° at a line stroke of 6 s.

Contact us

Are you interested in ELVAC Vision and want more information?

Martin has been implementing machine vision at ELVAC for many years. He can help you choose the right solution to meet your exact needs.