Separate workstation for application and curing of transparent silicone

The main task in this case was to create a reliable system for controlling the application of transparent silicone on printed circuit boards using ELVAC Vision.

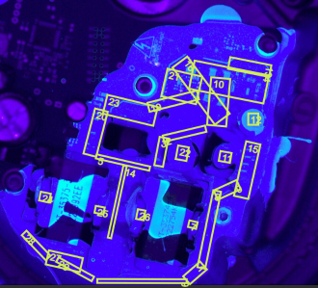

The solution was implemented by deploying a powerful high-resolution camera with industrial lighting in the UV spectrum. For image analysis we used neural networks. The system thus created allows for detailed inspection of dozens of zones on each PCB, with sizes as small as 4 mm².

The ELVAC Vision implementation delivers maximum control accuracy and reliability to ensure an error-free production process. In addition, thanks to the quick definition of inspection zones, our machine vision system can be easily deployed on new product types.

The key strengths of ELVAC Vision in this project are:

- Use of neural networks

- Using industrial light in the UV spectrum to highlight silicone

- Choosing a camera with sufficient resolution to detect zones as small as 4 mm²

Contact us

Are you interested in ELVAC Vision and want more information?

Martin has been implementing machine vision at ELVAC for many years. He can help you choose the right solution to meet your exact needs.