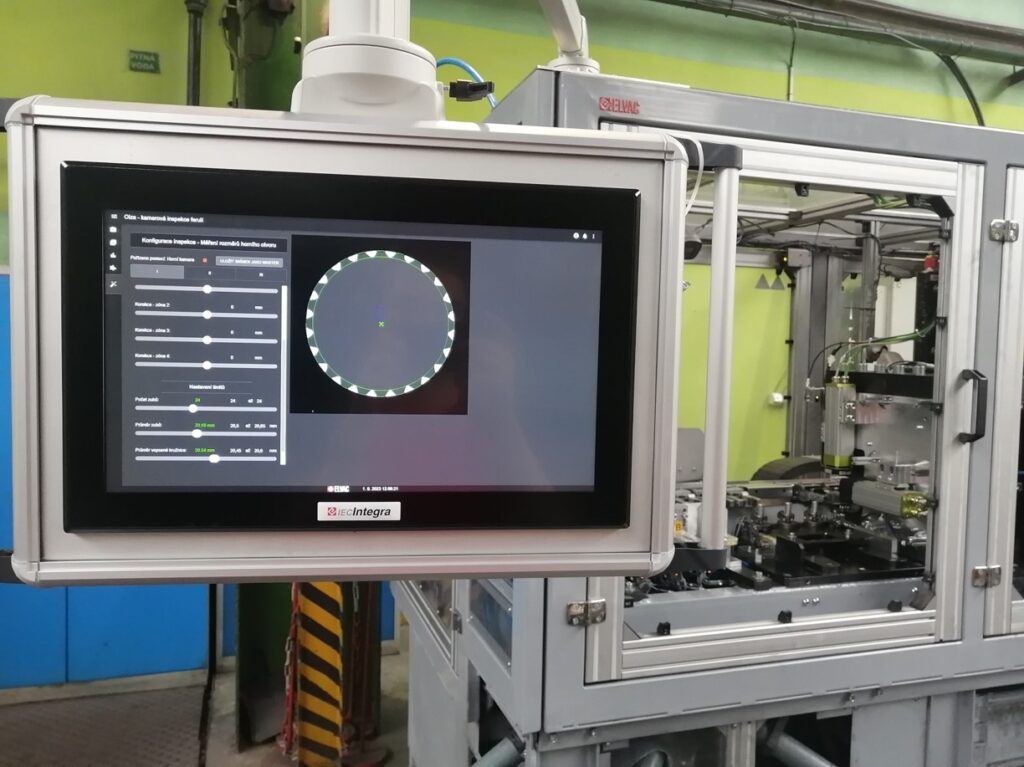

Integration of precision camera part measurement into an older machine

Due to the increased demands on product quality, we added optical measurement with an accuracy of ± 0.1 mm and evaluation of the results within 100 ms.

For this purpose, we have installed two cameras with powerful flash lights that provide sharp and detailed images of the parts even at conveyor speeds exceeding 2 m/s. And because the distance of the objects from the cameras is variable, we have also implemented a sophisticated correction of the measured dimensions based on the height of the product. This allows the system to achieve accurate and consistent measurements.

ELAC Vision has significantly increased the accuracy of output control, which has led to a significant reduction in the number of complaints for delivered products. In addition, the customer has gained important statistical data to assist in predictive machine maintenance.

The key strengths of ELVAC Vision in this project are:

- Accurate dimensional measurement with ± 0.1 mm tolerance

- Flash lights for sensing products in motion

- Evaluation of inspection results within 100 ms

Contact us

Are you interested in ELVAC Vision and want more information?

Martin has been implementing machine vision at ELVAC for many years. He can help you choose the right solution to meet your exact needs.