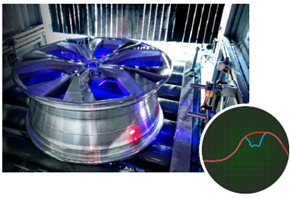

Measuring system for evaluating the surface quality of an aluminium wheel rim

In this project, we have developed a system that reliably detects porosity on machined aluminium wheels before they are painted.

Defect detection is based on scanning the rim with a 3D linear scanner while the wheel is rotated continuously. The evaluation of all scanned data is performed in an industrial PC.

We used precise 3D laser measurement to achieve porosity detection from 0.1 mm².

The key strengths of ELVAC Vision in this project are:

- 3D scanner integration

- Detection of defects on different types of wheels

- Intuitive setting of inspection parameters

Contact us

Are you interested in ELVAC Vision and want more information?

Martin has been implementing machine vision at ELVAC for many years. He can help you choose the right solution to meet your exact needs.